The steel pipe Ø219 metres was installed. Total length 18 metres. Depth of installation 2 metres. The machine used for the installation MAX K130S.

Two pipe sections, 9 meters each.

A large space around allows us to make long start pit. Otherwise, it would be necessary to cut the pipes into shorter sections.

We have to remember, before starting of making installation, to weld steel rings: one inside and one outside, at the beginning of steel pipe. As a result we achieve less friction between steel pipe and soil during installation. It will increase the total length of installed pipe and reduce the time of installation. How to make it, please look in the HOW TO DO section.

Using the excavator, first we had been making the End pit and Start pit. Then the steel pipe was placed in the Start pit.

The machine was mounted on a steel pipe. On the photo below we can see one mistake. The pipe was not mounted on the machine along the machine axis.

In this situation, not all the energy of the machine's impact is transferred to the pipe. The part of energy is wasted. And the instalation takes longer.

A simple mathematical relationship applies here:

F(useful) = F(applied) x cos α

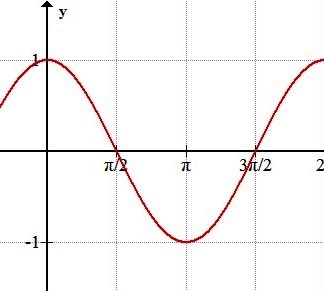

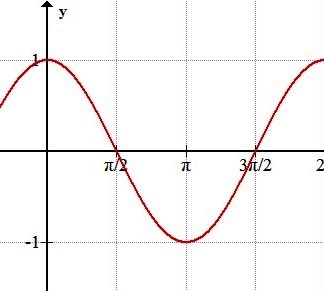

The α is an an angle betwwen axis of mole and axis of hammering pipe. As we know, the cosine function graph looks like this:

As an example: 10 degrees of deviation reduces the impact energy transferred to the pipe by about 20%.

Difficult ground conditions meant that the installation 18 meters of pipe lasted several hours. It was heavily compacted clay, which had no way to flow out during installation.

In such cases, it is worth making a hole at the end of the pipe. Or, instead of the ears welded to the pipe, make holes for mounting the fastening belts.

Finally tip: It is worth to protect the excavation walls. Otherwise the ground may flood the excavation and you will have to do the start pit and end pit again.

BACK |  Search

Search  Page map

Page map  E-mail

E-mail  Privacy policy

Privacy policy  Privacy policy |

Privacy policy |

back

back